Reservoir Management

Integrated Geoscience Interpretation

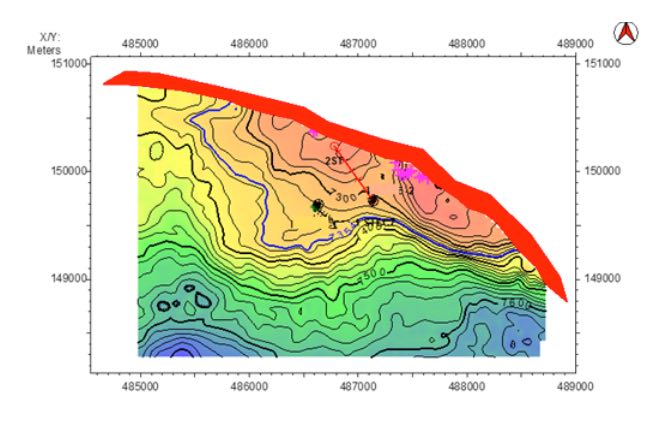

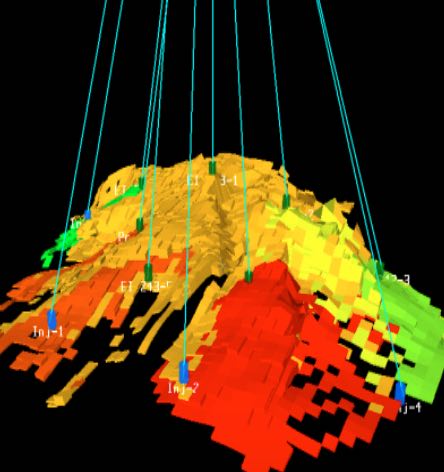

The objective is to build a reservoir model that is able to predict how a reservoir or formation will produce. Our goal is to determine the optimum set of subsurface conditions that will yield desired results and minimize costs through strategic future drilling and optimal selection of targeted zones.

Our team approach allows for geology, geophysics, petrophysics, and data management professionals to work together with all the information in a collaborative environment in order to more fully understand the reservoir architecture and the fluids they may contain.

Services include:

- Database creation management & quality control

- Prospect generation

- Structural & stratigraphic framework

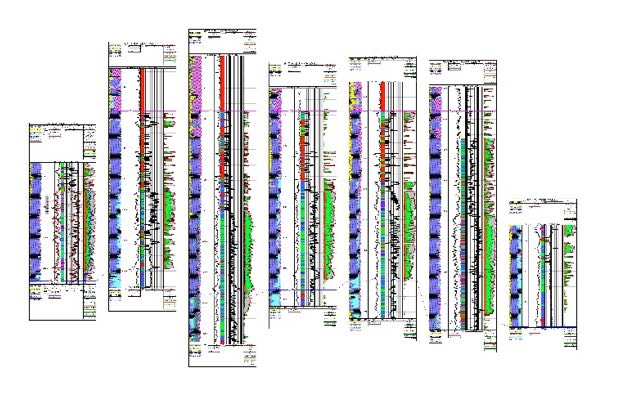

- Integrated petrophysical analysis

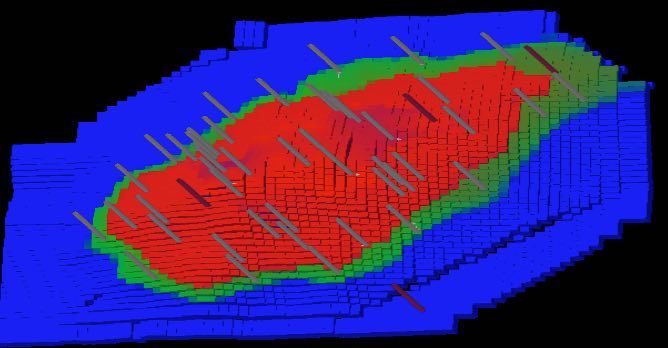

- Reservoir model construction

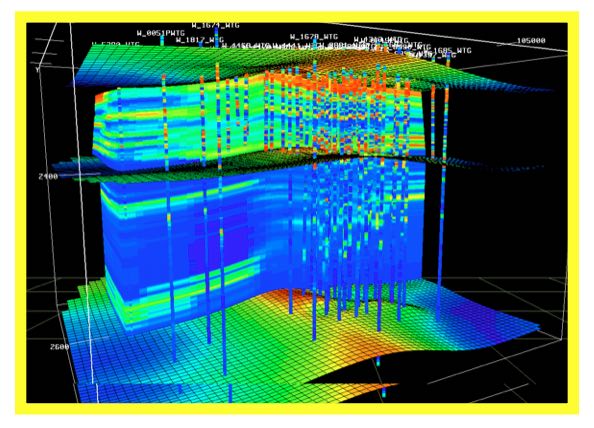

- 3D reservoir visualization

- Wellbore placement and reservoir exploitation modeling

- Preparation for reservoir simulation

Wallace International and its partners have at their disposal, cutting edge geoscience and software and computing technology. Our core applications run on a network PC system using Microsoft Windows 10 as our base operating platform. All our Geoscientists are competent users of:

In the end, our goal is to build the best reservoir model possible that utilizes all available data to determine the reservoir geometry along with its rock and fluid properties and predict the initial hydrocarbon in place prior to any production taking place.

Reservoir Engineering

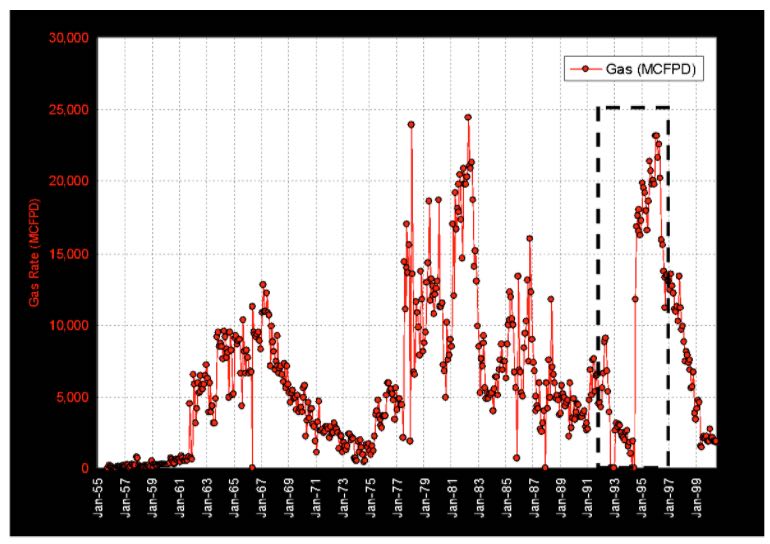

Once the reservoir model for the field is built, the next step in our reservoir management process is to predict, through various reservoir engineering modeling techniques, the dynamics of fluid flow and how it impacts recovery for the purposes of improving estimation of reserves and making decisions regarding the development of the field, predicting future production and performance, and to identify proper location of production and in-fill wells. Our technical Reservoir Engineering experts along with the G& G team will provide a complete integrated reserve and resource assessment, including reservoir simulation modeling, asset optimization, economic assessments and more to achieve a successful outcome. Reservoir assessments include:

Reservoir engineering studies

- Data QC working with geologist and geophysicist

- Dynamic and static pressure analysis

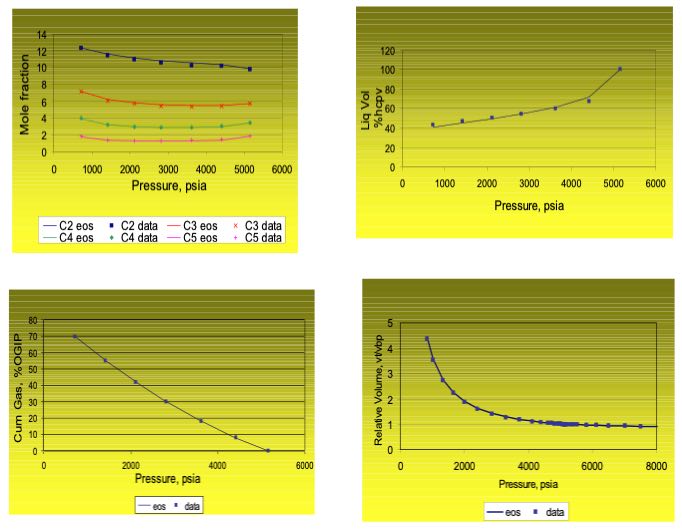

- PVT and fluid characterization including EOS modeling

- SCAL data including relative permeability and Capillary pressure

- Well test evaluation RFT and PLT analysis

- Production data QC and preparation for simulation use

Integrated reservoir simulation modeling

- Working with geologists and geophysicist prepare data for dynamic modelling:

- OOIP determination

- Determine optimal appraisal wells locations for new fields

- Determine infill wells locations for mature field

- Build a reservoir simulation model based on field type

- Black oil, compositional, Thermal, single, and dual porosity

- Single well /sector model for appraisal wells

- Full field model for mature reservoirs

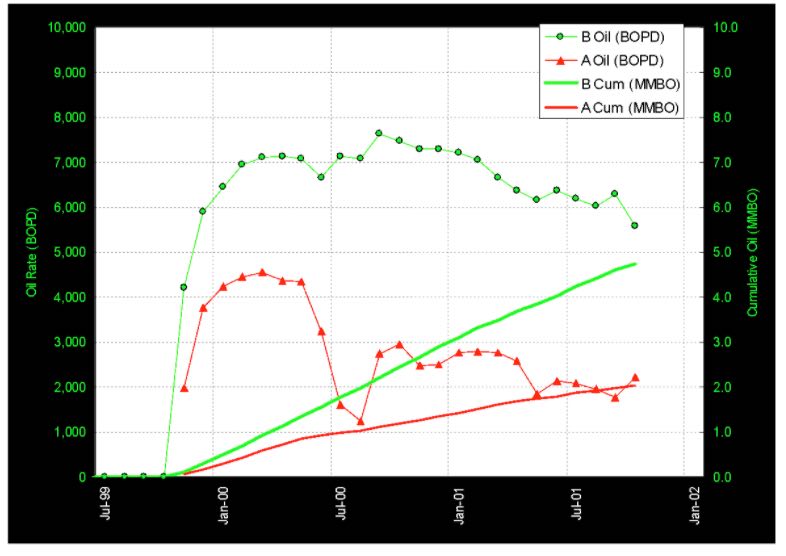

- History match and predict future performance and full field development plan

Improved oil/ enhanced recovery

- Infill drilling

- Horizontal/Multi-lateral wells

- Hydraulic fracture and multistage fracture evaluation.

- Artificial lift

- Water/gas/steam/chemical injection

Solving production problems

- Sanding

- Asphaltene Blocking

- Low productivity

- Water and gas coning

Economic Analysis

The economic evaluation and analysis of a field throughout the life of the producing reservoir(s), is needed to make sound business decisions to ensure that field will be economically viable (produce profits) to the Client up to the time of a field’s abandonment. Many scenarios are usually undertaken to predict risk and in the end choose the optimum project with the involvement of Client’s Management.

Economic assessments include:

- Payout time

- Profit-to-investment ration

- Present worth net profit

- Profitability index

- Discounted cash flows

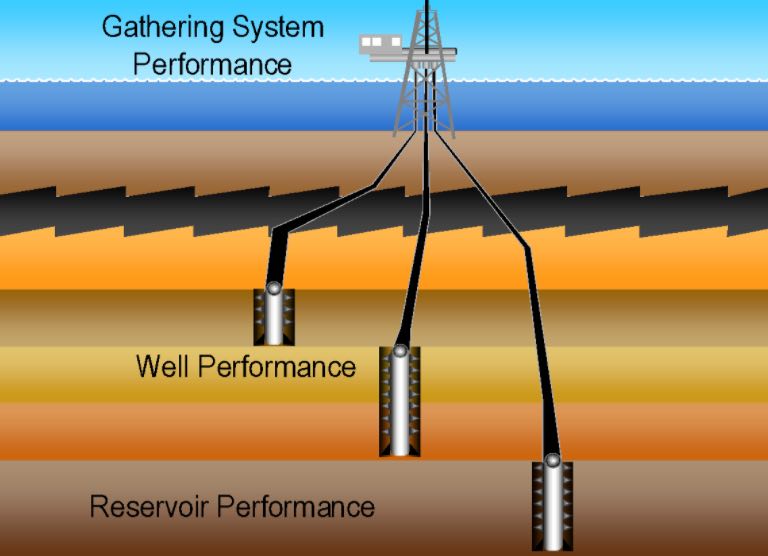

Production Engineering Assessments

We optimize production (or injection) using reservoir management protocols in a cost-effective manner for Clients, emphasizing on single-well performance and production or injection optimization and may also serve as a boundary condition in a field-wide, long-term reservoir engineering study.

Our engineers use the findings from the Reservoir Modeling effort including material balance calculations or reservoir simulation to further define and refine the forecasts of well performance and allow for more appropriate production engineering decisions.

Another words, Reservoir management is the dynamic process that identifies the uncertainties affecting the future field behavior and tries to reduce their impact by optimizing the field performance through a systematic application of integrated, multidisciplinary technologies.

Completions Engineering

- Model sanding risk

- Model perforating system impact

- Model formation damage impact

- Analyze well reliability

- Determine optimal sand-face completion design (vertical / horizontal)

Quantitative theoretical, experimental and field data analyses integrated with reservoir characterization yields the optimal lifecycle completion design

Field Surveillance

Using proven tools and processes

- Organize, process and quality-check field database

- Build and analyze quantitative systems models: reservoir, well, pipeline network

- Develop understanding: reservoir, well, system dynamics

- Value-based recommendations for implementation

Monitor, model system infrastructure to track progress and forecast performance

Production Optimization

- Field data review

- Integrate formation, well, system data

- Analyze well inflow performance

- Quantify uplift opportunities

- Debottleneck system

- Diagnose water breakthrough

Model system design and operations to: identify, validate and capture stranded value.

Production engineering assessments include:

- Identify production bottlenecks via systems analysis

- Implement field projects to enhance productivity

- Gas lift design & operation

- Gas compressor studies

- Manage production decline

- Manage gas/water influx