Metallurgical & Corrosion Engineering

Wallace International, LLC has formed a joint partnership with ACME, LLC a material science and corrosion R & D and consulting services company, to better serve our clients’ needs in materials and corrosion engineering.

Materials & Corrosion Engineering

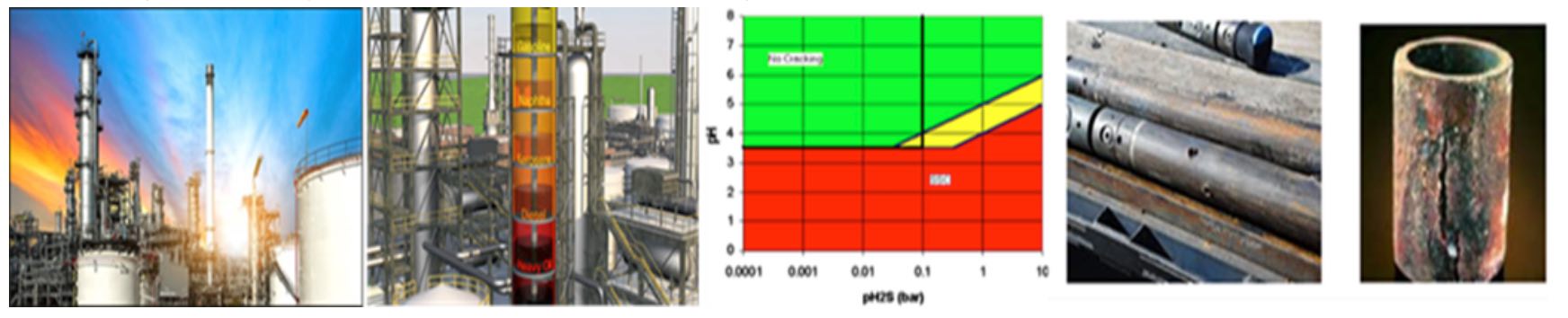

ACME experts are specialized in Forensic Materials Failure Analysis of metallic components and in providing corrosion consulting and material selection services to clients in Oil & Gas industries. ACME Consulting Engineering provides a comprehensive suite of materials and corrosion engineering services including root cause analysis (RCA), integrity management plans, pipelines, refineries, tanks, pressure vessel (PV), cathodic protection, subsurface corrosion challenges, materials selections/Corrosion Resistant Alloys (CRAs) in sour service, materials & Corrosion integrity in gas plants, welding, Engineering Critical Assessment (ECA), materials for use in oil & gas (CO2 (sweet), H2S (sour) & Chloride), hydrogen embrittlement, and other structures.

ACME is a team of engineers and senior scientists with multidisciplinary competence, solving complex problems, capable of delivering value-driven engineering with unparalleled expertise. Frequently ACME’s experts are invited to provide professional consulting services for companies in the oil and gas and other industries as well as corrosion training. ACME’s team worked with various institutions, government agencies, and private companies throughout their careers.

- Managed root-cause-analysis (RCA)

Stress corrosion cracking (SCC)

◦ Fatigue cracking

◦ Sulfide stress cracking (SSC) - Corrosion Forensics

- Hydrogen embrittlement

- HIC, SOHIC, Sour service

Corrosion Control & Materials in Oil & Gas Production

- Problems encountered in wet H2S

- Hydrogen-induced cracking (HIC)

- Sulfide stress cracking (SSC)

- Stress-Oriented HIC (SOHIC)

- Hydrogen damage assessments

- Hydrogen-permeation – Field & Laboratory.

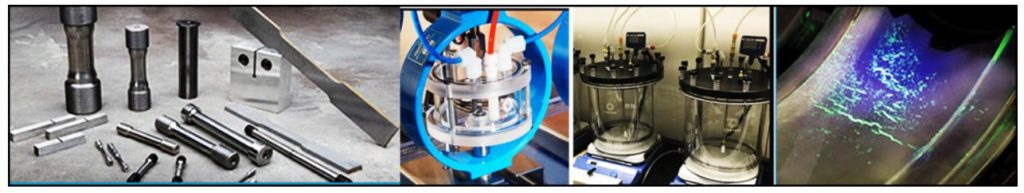

- Full-scale Tests

- Double cantilever beam (DCB);

- Wedge open load (WOL);

- Compact tension (CT);

- Three and four-point bending (4-pt.b.); C-ring, etc.