Wallace International Field Case Study

INTRODUCTION

Our “Client” commissioned Wallace International, LLC (WI) to provide a detailed petrophysical field study of a legacy oil property that had been in rapid decline. The Client purchased the field with hopes to deploy Enhanced Oil Recovery (EOR) stimulation to extract any remaining oil as long as it was economic to do so. As with any successful EOR program, adequate sampling of the reservoir rocks and their fluids is needed.

In order to move forward with this strategy, Wallace International, LLC provided a more integrated geoscience approach to understanding the subsurface geology, rock fabric, flow units, permeability and fluid saturation. Acquiring a correct interpretation of the formation logs as well as incorporating core and historical production records is of utmost importance that will aid in assigning economic value to the hydrocarbons that remain and what is possible to recover.

HISTORY

The 6,000 plus acre field was discovered in the late 1930’s, with most of the initial development occurring during the 1940s. The Client speculated that meteoric water had swept through various fairways through the reservoir during the Late Cretaceous-Early Tertiary that left behind a significant amount of free and residual oil. Nearly 80 million barrels of oil of the estimated 740 million barrels of the original oil in-place had been produced by the time it had reached its economic life. At least, that was what the previous Owners had thought.

A FRESH LOOK

The Client wanted an updated characterization study to improve its understanding of the subsurface rock and fluid properties, and a comprehensive 3D geological model for the field. The Client believed that these updates and enhancements would support the strategy for Enhanced Oil Recovery (EOR) efforts

and potentially predict EOR performance. The efficiency of any EOR method depends on (a) the reservoir characteristics, (b) The nature of the displacing and displaced fluids, and (c) The arrangement of production and injection wells. Wallace International, LLC’s role was to provide a rigorous petrophysical rock and fluid properties evaluation, develop a prediction method for flow unit delineation and permeability, and if possible, estimate historical and current oil in place volumes and range of the potential recoverable oil.

The Client provided Wallace International, LLC (WI) with well data from eight “key” wells, two wells were completely cored through the main pay zone. These key wells had the best well data sets available of the nearly 70 wells that had been drilled over time and were logged with more modern logging devices within a 3-year period. The pay zone consists mainly of Dolomite with some secondary minerals of quartz, calcite and anhydrite. The whole core photos showed significant intervals of intercrystalline rock with some internals of pin-point moldic to vugular porosity including several ‘healed’ fractures. A few random open vertical fractures were also present in the core record, but were not pervasive. Oil florescence was observed throughout with the exception below the 100% water contact (zero capillary pressure).

All borehole measurement data (core and logs) were checked for any issues caused by borehole effects, calibration issues and ensured that proper depth control was implemented, especially when aligning core data with log measurements. The modern logging suites included spectral gamma ray, Laterolog resistivity, spectral density, compensated neutron porosity and compensated acoustic measurements. Core measurements that were available included: routine core data (porosity, grain density and air permeability), X-ray diffraction (XRD) in weight %, capillary pressure data, relative permeability data, and Dean-Stark saturation measurements.

Lithology (mineralogy) and porosity was calculated using multi-log measurement matrix inversion modeling. This form of machine learning modeling minimizes the error that is inherent in deterministic single log porosity solutions especially when working in complex lithology. The core XRD data and the routine core analysis data from the two key cored wells were used in developing field-wide lithology and porosity matrix inversion models and then were applied to all wells that were part of this study.

Figure 1. shows an example of the results from inversion modeling. Each lithology is broken out into separate tracks with the XRD and routine core porosity data is also plotted as dots alongside each inversion analysis result. A reasonable fit is observed.

In addition to resolving the lithology and porosity of the reservoir, the Client was most interested in knowing more about the rock fabric of the reservoir, the permeability and a more current fluid saturation estimation. A more robust prediction of the rock fabric would be needed to assess flow paths between wells in order to target zones needed for a successful EOR project.

Figure 2 shows some slabbed core from the reservoir and the types of rock fabric (pore types) that is pervasive throughout the producing interval.

Core Slab A

Show dolomite with open vugs that are lined with anhydrite crystals. The vugs do not appear to be well connected in this

view, however, it’s quite possible that the connected vugular networks may form elsewhere on the reservoir. This pore type could provide high permeability and good for EOR enhancement.

Core Slab B

Show vugs completely filled with anhydrite. Making this rock a poor candidate and very low permeability.

Core Slab C

Show dolomite with several healed and few open fractures throughout. One can expect low to moderate permeability depending if more open

fractures are present. Finally, core slab D. shows an intercrystalline dolo-mudstone. This rock type can have poor to fair porosity but expect low permeability. Given these complex rock fabrics, attempting to model permeability using linear RMA correlation routines will yield a substandard result

Hydraulic Flow Unit Modeling

The concept of hydraulic flow units can be used to predict permeability with reliable accuracy. Amaefule et al. (Enhanced Reservoir Description: Using Core and Log Data to Identify Hydraulic (Flow) Units and Predict Permeability in Uncored Intervals/Wells) considered the role of the mean hydraulic radius in defining hydraulic flow units (HFU) and correlating permeability from core data. Their approach was essentially based on a modified Kozeny-Carmen equation coupled with the concept of mean hydraulic radius. Amaefule et al. determined the basis of HFU classification is to identify groups of data that form unit-slope straight lines on a Log-Log plot of reservoir quality index (RQI) versus porosity (ø), as shown in Figure 3.

Flow zone index (FZI) is then correlated with certain combinations of logging tool responses to predict permeability values in cored and un-cored intervals of wells. This method attempts to identify the flow zone indicator in un-cored wells using log measurements. Once the FZI is calculated from the core data, a relationship between this FZI value and the well logs can be obtained. The FZI is then correlated with logging measurements to develop models for permeability predictions in cored and un-cored wells. The permeability can be computed for those points on the same straight line (with same FZI) as shown in Figure 4 below.

Flow zone permeability (FZI) modeling provides a method for delineating the number of layers (hydraulic units) that are present in the producing reservoir and improves the prediction of permeability and permeability distributions from wireline logs in partially cored/un-cored intervals and near-by wells slated as part of the EOR project.

Flow zone permeability modelling begins with the prediction of hydraulic flow units (zones) shown in Figure 4 (in color) is also presented in the plot shown in Figure 5 using the same color format. The flow zones are then used to calculate the permeability similarly shown on Figure 4. This procedure is performed for all the wells that fall within the EOR project area. It provided guidance to the Client on what zones to flood and what zones to avoid getting the optimum result. The targeted zones selected were green, yellow and magenta colors. These flow zones represent permeability zones that are above 1 mD but less than 10 mD’s and are concentrated in regions that still have sufficient hydrocarbons remaining.

Fluid Saturation Modeling

First, a core capillary pressure-based water saturation model was composed to derive apparent original water saturation, pre-initial production. The Skelt saturation-height function model was constructed using a significant amount of core capillary pressure data representing a range of permeability in order to predict the original water saturation in all the wells, especially for wells that were part of the EOR project. An original oil-in-place per acre at the time of initial field development can now be estimated. Next, the prediction of the current fluid saturation was undertaken using the core “Dean-Stark” saturation data along with log resistivity and porosity data that were taken within a few years’ time range.

A log-based, core calibrated water saturation model was built and implemented on wells drilled within the field to predict ‘current’ remaining oil-in-place per acre. Included in the core database, were core residual oil saturation measurements. These data were used to build models that would predict the residual oil saturation and the Residumm (tar/bound hydrocarbon).

This proved invaluable when it came to better understand where the reservoir fluid levels stood during the time period chosen, especially in the wells that were part of the EOR project. It helped to pin-point intervals that still had free oil remaining, as well as, an indication of the potential residual oil volumes that could be swept by gas-induced injection. It also allowed the Operator to determine the type of EOR program to apply to the reservoir to maximize the economic recovery of the remaining hydrocarbon.

Figure 6. shows one of the “key” wells’ final petrophysical properties analysis plot from which all the core based models were derived and then implemented on the remaining wells in the study. The core data measurements are plotted on exactly the same scale as their log-derived counterparts. Given the heterogeneity of the rock, the modeling effort does a nice job of predicting both the rock and fluid properties. Now, the Operator, with a high degree of certainty, can construct a secondary or tertiary recovery program that targets zones that will give maximum economic benefit.

FINAL RESULTS

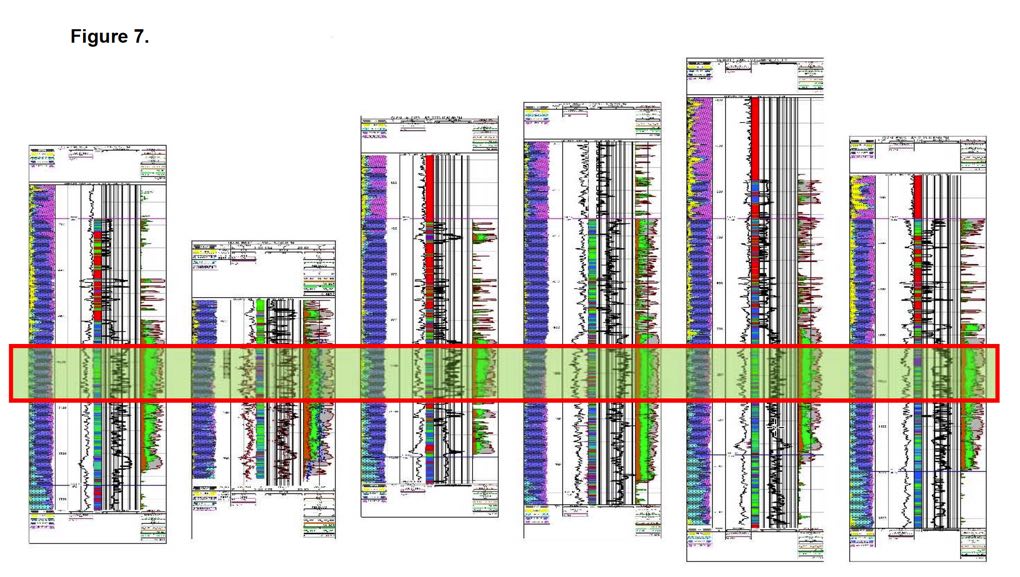

Figure 7 show the cross section of wells that surround the injector in a seven spot pattern. The goal is to select zone(s) that will yield the best effectiveness or sweep efficiency and long term performance. Clearly, there are many considerations that need scrutiny, but this is a great first step in the decision making process in selecting zones that will yield a long flood life. The green shaded area was recommended based on properties and common hydraulic flow zones observed from the analysis.

Additionally, selecting or targeting a zone of interest, also requires some knowledge in how much hydrocarbon can be ultimately recovered. Figure 8 below shows a table that Wallace International, LLC constructed to provide the Operator economic information in terms of barrels of potential recoverable oil and projecting potential income from those recoverable liquids. The numbers speak for themselves. Based on this analysis, there is considerable amount oil left behind by the previous Owners. This particular field could produce an extra 50 million to over 100 million barrels of recoverable oil. That’s significant. The Operator proceeded with the EOR operation, in fact, several EOR projects were constructed for the field. Excellent results have been achieved.