Today, American citizens find themselves pondering the allure of royalty payments and good paying jobs from gas and oil well exploration and production investments. Their dilemma is mitigating the risk of adversely affecting ground water (aquifers) and severely affecting sensitive surface environments.

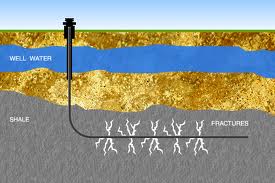

Hydraulic fracturing is at the forefront of this debate. Without hydraulic fracturing or fracking, oil and gas operators would not be able to unlock otherwise unobtainable vast petroleum reserves from shale and other semi-impermeable reservoirs. Hydraulic fracturing has been around since 1949 when Stanolind Oil & Gas Company first used it in a well to increase initial hydrocarbon flow and maximize the recovery of oil. Since that time, more than three million fracture treatments have been performed in oil and gas wells around the world.

Is Fracking Safe?

But is it safe? “In this world nothing can be said to be certain, except death and taxes.” This was immortalized by the great American, Benjamin Franklin in The Works of Benjamin Franklin 1817. And this thought continues to hold true even now, even with hydraulic fracturing.

As an Oil & Gas Operator, there are mechanisms that can be put in place to minimize the risk of a potential environmental accident. Remember, the Operators main objective is to stimulate the subsurface formation that is typically more than a mile below the surface, to maximize oil and gas production and recovery. Many of the people who work in the Industry live in these communities as well, and do not want to jeopardize their community’s environmental habitat. Here is a partial list of strategies an Operator may use to refine its fracture stimulation design.

- Understand and respect the surrounding regional geology (large open natural faults and fissures). When pumping large volumes of fluid and proppant at high pressure, it is possible that the liquids could break into open faults and cause a minor earthquake and allow frac fluids to migrate upwards into near surface aquifers.

- Locate nearby “orphaned” (abandoned) wells that have penetrated the zone that will be stimulated and determine if casing integrity and cement seal is adequate in order to mitigate risk of “frac” fluid and in-situ reservoir fluid contamination. Older abandoned wells could potentially be a concern because casing and cement integrity over time will degrade. The frac could intercept these older abandoned wells and travel up an annulus created by the high pressure frac fluid and well casing/cement degradation.

- Ensure there is excellent cement bond between the pipe and rock from surface through the targeted zone. Well construction issues and petroleum seepage from poor well completions, especially closer to the surface could potentially cause an increased risk of contamination. Mitigate risk by using cement evaluation log survey to locate poor cement bonding, if any, and any cement annulus issues.

- Do a detailed petrophysical property analysis to estimate reservoir mineralogy, porosity/porosity type, fluid saturation, organic content and geo-mechanical measurements.

– Identifies best zones to perforate and give the best opportunity for optimal stimulation.

– Location of brittle and ductile zones. Ductile formations above the stimulation zone are important to limit the fracture stimulation from going beyond the intended target area. The more brittle the rock the better it will break and cause a fracture to occur.

In the end, the chances of creating a flow path to the surface that contaminates groundwater or the surface from hydraulic fracturing are small. The Industry will continue to use hydraulic fracturing as a tool to stimulate formations including shale. We will continue to see rapid improvement in the technology, especially in the area of non-toxic stimulation fluids and fracture design. Let’s continue to work on becoming the best at hydraulic fracturing. The world is counting on us.

–– James Wallace, Wallace International, LLC

Leave A Comment