Welding Metallurgy and Weldability

Welding Metallurgy and Weldability

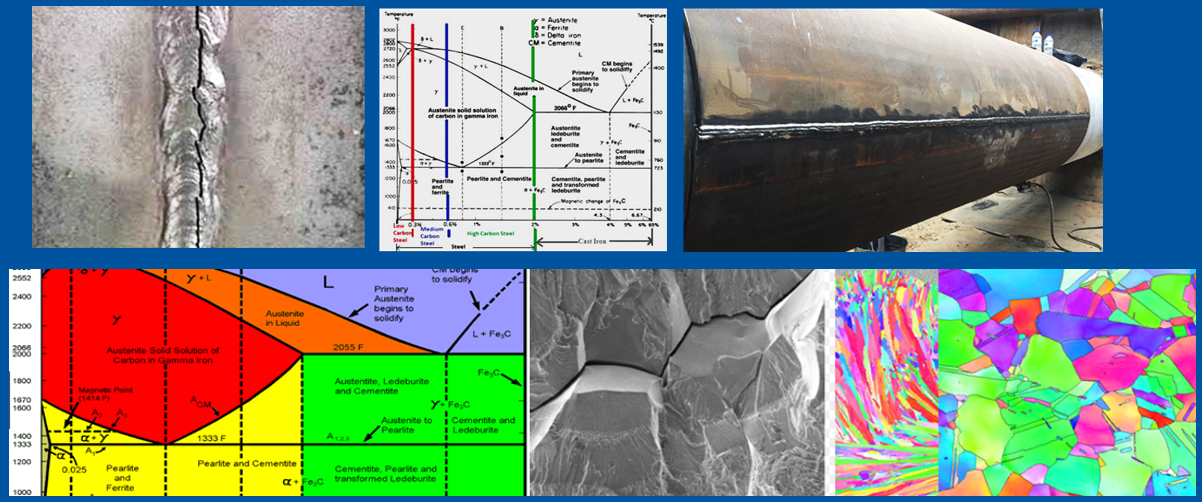

This course provides an understanding of the properties of the makeup of alloys and the effects of joining methods on their microstructures is crucial to ensure the performance of components and structures in service.

Welding is therefore a special process. It brings together the disciplines of design, metallurgy, process and inspection. It is probably one of the most governed activities in the world. Governed by National and International Codes and Clients/Customer Specifications.

The course will cover:

- In-depth knowledge on metallurgy and welding technology including, fabrication and inspection in accordance with American Welding Society (AWS), ASME and API codes & standards

- Differentiate the various welding process such as SMAW, GMAW, GTAW, FCAW and OAW

- Review arc welding consumables including welding wires, coated electrodes, sub arc wires and fluxes, neutral and active fluxes and shielding gases

- Review the properties and strength of materials and carryout destructive testing

- Analyze the fatigue of welded structures, joint design as well as dissimilar welds and weld overlays

- Characterize the metallurgical properties of steel and heat-treatment and implement welding quality control

- Review the latest standards and procedure for welding pipeline

- Review welding safety with proper procedure and specification

More information can be found in the Services section of this website.

Class Information

Field: Materials Engineering

Instructor(s): Dr. Magdy Girgis & Dr. Mimoun Elboujdaini

Current # Registered: 00

Session Schedule

Virtual Zoom Class

URL will be emailed once payment has been received

Start time: 9:00AM CST (5 hours per day)

Start Date: November 1st, 2021

— In Person Training —